- 1. Introduction

- 2. Overview of Two Surface Treatment Technologies

- 3. Detailed Comparison: Anodizing vs. Powder Coating in GMP Cleanrooms

- 4. Which Option is More Suitable for Each GMP Area?

- 5. Expert Insight: When Should You Prioritize Anodizing?

- 6. Frequently Asked Questions

- 7. Conclusion & Recommended Action

1. Introduction

In the design and construction of GMP cleanrooms—especially in the pharmaceutical sector—every detail must strictly comply with hygiene, cleanliness, cross-contamination prevention, and maintenance standards. Among these, surface finishing materials for metal structures and equipment (such as workbenches, stainless steel cabinets, door frames, pass boxes…) play a critical role, directly affecting the long-term operational stability and GMP compliance of the facility.

Two popular surface treatment technologies widely applied in industrial settings are anodized aluminum and powder coating. However, when implemented in GMP cleanroom environments—where resistance to chemicals, dust accumulation, and ease of cleaning are crucial—the choice of surface treatment becomes a key consideration.

So, between anodizing and powder coating, which technology is truly more suitable for GMP-compliant cleanrooms—especially in modern pharmaceutical plants?

This article will provide a comprehensive comparison based on technical criteria, real-world applications, and expert insights from cleanroom professionals.

2. Overview of Two Surface Treatment Technologies

When selecting metal materials for GMP cleanroom equipment, the surface finish is one of the top priorities. The two most common surface finishing methods today are anodizing and powder coating, each with its own mechanism, properties, and application scope.

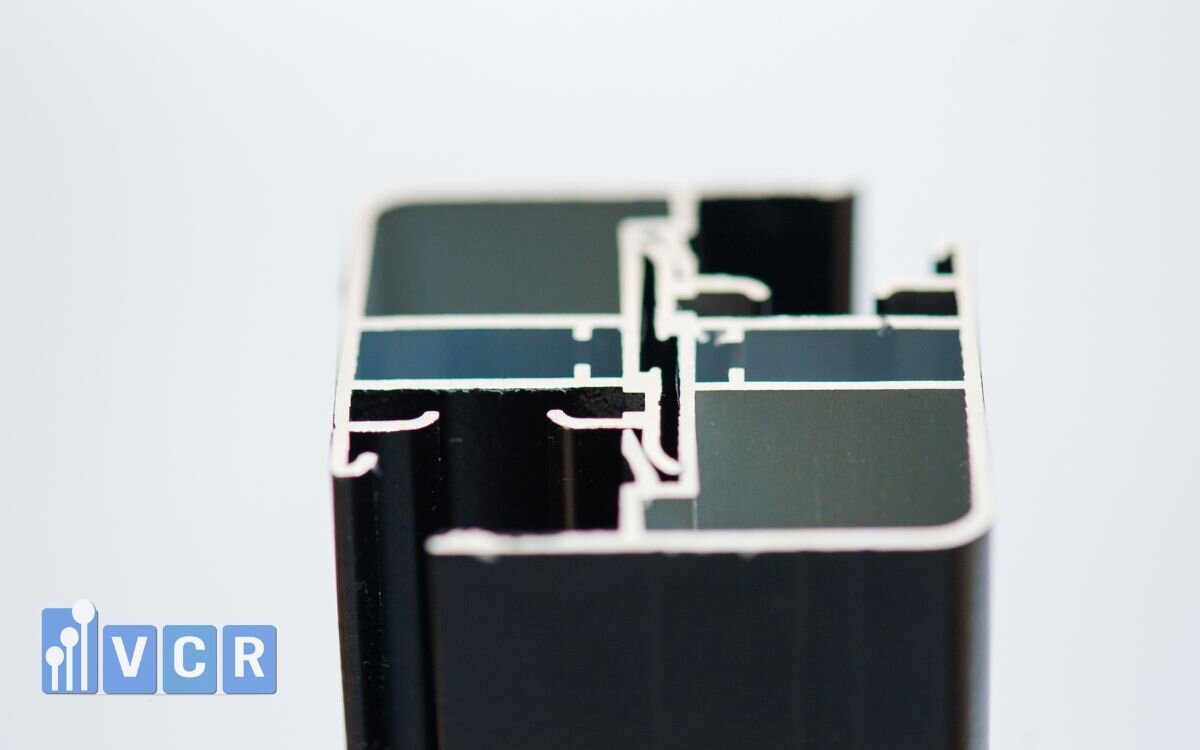

2.1 What is Anodizing?

Anodizing is an electrochemical process in which the surface of aluminum is transformed into a layer of aluminum oxide (Al₂O₃) that is hard and tightly bonded to the base metal. This is not an external coating, but a protective oxide layer generated from the material itself.

Key characteristics of anodized aluminum:

- Highly resistant to corrosion and chemicals, including mild acids/alkalis commonly used in cleanroom sanitation.

- Hard surface with excellent scratch resistance, reducing microbial adhesion.

- Limited color options (typically matte silver or black) due to the non-pigmented treatment process.

- Smooth, easy-to-clean surface, ideal for GMP cleaning protocols.

Applications: Widely used in industries requiring high precision and hygiene such as medical devices, electronics, aerospace—and especially pharmaceutical cleanrooms.

2.2 What is Powder Coating?

Powder coating involves applying a dry powder onto the metal surface using an electrostatic charge, then curing it under heat to form a solid, uniform finish. The powder is drawn to the metal surface due to electrostatic attraction.

Key characteristics of powder coating:

- Wide color range, allowing for aesthetic customization in cleanroom designs.

- Easy to apply, with short processing time.

- Lower cost compared to anodizing.

- Moderate chemical resistance and hardness, depending on the type of powder and application conditions.

Applications: Common in furniture, industrial equipment, metal frames, and some technical cabinets in cleanrooms where high GMP standards are not mandatory.

3. Detailed Comparison: Anodizing vs. Powder Coating in GMP Cleanrooms

In pharmaceutical GMP cleanroom environments, selecting a surface finish involves more than aesthetics or cost—it must consider chemical resistance, cleanability, and regulatory compliance. Below is a detailed side-by-side comparison:

|

Evaluation Criteria |

Anodized Aluminum |

Powder Coating |

|

1. Resistance to Acid/Alkali Cleaners |

High - Not corroded by standard GMP cleaning agents |

Moderate - May peel when exposed to strong solvents |

|

2. Cleanability & Dust Resistance |

Excellent - Smooth surface, easy to wipe, no dust retention |

Moderate - Can scratch over time, trapping contaminants |

|

3. Aesthetic & Color Options |

Limited - Mostly matte silver or black |

Versatile - Wide range of colors for design consistency |

|

4. Mechanical Strength & Scratch Resistance |

Very High - Hard oxide layer, extremely durable |

Good - Tougher than paint, but less durable than anodizing |

|

5. Production Cost |

Higher - Complex processing |

Lower - Fast and cost-effective |

|

6. GMP Compliance |

Optimal - Preferred for Grade A-B areas |

Needs validation - Not all powder coatings meet GMP standards |

Conclusion:

- Anodizing is ideal for equipment and zones requiring absolute hygiene, such as weighing rooms, compounding areas, and aseptic filling zones.

- Powder coating is acceptable for less critical areas, such as utility corridors or material staging zones, where direct contamination risks are minimal and cost-saving is prioritized.

4. Which Option is More Suitable for Each GMP Area?

In a GMP cleanroom, each functional zone has different requirements for hygiene and microbial control. Therefore, choosing between anodized aluminum or powder coating must be based on the cleanroom grade and the frequency of exposure to cleaning agents and manual handling.

1. Grade A-B Areas: Where Anodizing is Mandatory

These are zones with the strictest hygiene requirements, such as:

- Compounding rooms

- Aseptic filling rooms

- Weighing rooms

- Injectable packaging areas

In these critical environments, anodized aluminum is the preferred choice because it:

- Offers absolute resistance to cleaning agents like IPA, H₂O₂, ClO₂

- Has a hard, scratch-resistant surface that prevents microbial harboring

- Is easy to clean and does not peel or flake, ensuring EU-GMP hygiene compliance

2. Grade C-D & Supportive Areas: Powder Coating is Acceptable

These areas have lower contamination control requirements, such as:

- Utility corridors

- Packaging and raw material storage

- Semi-finished product inspection areas

In such zones, powder coating is a more economical option if:

- High-quality coatings are selected and verified for VOC-free emissions

- The equipment is installed in locations with minimal exposure to cleaning solutions

- Gentle cleaning protocols are applied to minimize surface abrasion

3. Recommendation: Smart Material Selection Based on Function and Usage Frequency

|

Area |

Recommended Material |

|

Grade A-B (aseptic, weighing, compounding) |

100% anodized aluminum |

|

Grade C-D (production support) |

Anodized or high-grade powder-coated finish |

|

Corridors, storage, technical zones |

Powder coating to optimize cost |

Note: Do not base your decision solely on upfront investment. Consider total lifecycle costs—maintenance, cleaning, and GMP compliance risks. In many cases, anodizing may be more economical in the long run.

5. Expert Insight: When Should You Prioritize Anodizing?

Beyond technical merit, anodized aluminum is often considered a key GMP compliance factor during audits—especially in facilities targeting EU-GMP, PIC/S, or WHO-GMP certification.

GMP QA expert comment:

“In GMP audits of pharmaceutical plants, equipment with anodized surfaces is generally rated higher due to their non-peeling nature, dust resistance, and ease of disinfection. Some foreign auditors even recommend removing all coated surfaces—including powder-coated ones—in Grade A and B zones.”

— Nguyen L.T., QA Manager, EU-GMP certified pharmaceutical plant

Why Auditors Prefer Anodized Finishes:

- No flaking or surface degradation—a common GMP failure with coated metals

- No retention of microbial contaminants or chemical residue after cleaning

- Long-lasting durability without discoloration or frequent maintenance

Real-world example from a VCR-implemented pharmaceutical project:

In a cleanroom project for an injectable antibiotic facility (Grade A/B), VCR utilized 100% stainless steel equipment with anodized aluminum components, including:

- Cleanroom door frames

- Cabinet handles

- Stainless steel racks with anodized aluminum modules

After two years of operation:

- No signs of peeling, discoloration, or corrosion were recorded

- Daily cleaning with 70% IPA had no adverse effect on the surface finish

- International auditors assessed the facility as “clean surface ready for sanitization without risk”

Expert conclusion:

If you are building a GMP-compliant cleanroom, especially for injectable production, anodizing is almost a must-have. It’s not only a durable solution but also a strategic choice to facilitate a smooth audit process.

6. Frequently Asked Questions

1. Is anodized aluminum more durable than powder coating in cleanrooms?

Yes. Anodized aluminum offers superior resistance to corrosion, chemicals, and scratches. Especially in GMP cleanrooms frequently exposed to IPA, H₂O₂, or disinfectants, anodizing ensures the surface remains clean and intact over time.

2. Can powder coating be used in microbiological testing areas?

Not recommended. Micro labs require surfaces that are non-porous, easy to clean, and resistant to microbial retention. Powder coating, although aesthetically pleasing, can scratch over time—creating hiding spots for microbes, making it hard to control contamination, and potentially non-compliant with GMP.

3. Is anodizing significantly more expensive?

It is more costly upfront—typically 20-30% more than powder coating. However, when factoring in product lifecycle, maintenance, and GMP risk reduction, anodizing is often the more economical and safer long-term choice.

7. Conclusion & Recommended Action

Choosing between anodized aluminum and powder coating is not merely a technical matter—it directly impacts GMP compliance, operational costs, and long-term hygiene safety in pharmaceutical cleanrooms.

Anodizing is the optimal choice for high-critical areas like weighing rooms, compounding zones, and aseptic filling areas—where auditors conduct the most rigorous inspections.

Powder coating is suitable for support zones, utility corridors, or when budgets are constrained—but its application must be closely controlled in terms of coating quality.

Expert tip: If you're designing or upgrading a GMP cleanroom, clearly define the cleanroom grade of each area before selecting surface materials. This helps avoid costly mistakes and audit failures.

Need help choosing cleanroom materials that meet GMP standards?

The engineering team at VCR - Cleanroom Equipment is ready to assist you with:

- Zone-specific GMP compliance analysis (Grade A → D)

- Cost-audit-performance-based material recommendations

- Material samples and rapid quotation service

Contact us now at:

Hotline: 090.123.9008

Email: [email protected]

Website: https://phongsachduocpham.com

Diep VCR

Vietnam Cleanroom (VCR) là một doanh nghiệp hàng đầu tại Việt Nam chuyên cung cấp thiết bị và giải pháp phòng sạch. Với hơn 10 năm kinh nghiệm phục vụ các dự án phòng sạch đạt tiêu chuẩn GMP, VCR tự hào mang đến các thiết bị kỹ thuật cao như: đồng hồ chênh áp, khóa liên động, đèn phòng sạch, Pass Box, FFU (Fan Filter Unit), buồng cân, HEPA Box, Air Shower, cửa thép phòng sạch, tủ cách ly (ISOLATOR), và nhiều loại phụ kiện chuyên dụng khác

Không chỉ là nhà cung cấp thiết bị, VCR còn là đơn vị phân phối độc quyền các sản phẩm từ các thương hiệu quốc tế như LENGE và BLOCK Technical, đồng thời cung cấp các giải pháp phòng sạch toàn diện cho các lĩnh vực như dược phẩm, điện tử, y tế, thực phẩm và mỹ phẩm. VCR có đội ngũ chuyên gia giàu kinh nghiệm, kiến thức chuyên sâu về phòng sạch, hỗ trợ tư vấn về tiêu chuẩn, thiết kế, thi công và vận hành phòng sạch theo chuẩn ISO, GMP, HACCP, ISO 14644

VCR hướng đến trở thành thương hiệu quốc dân trong ngành phòng sạch, với mạng lưới cung ứng rộng khắp, VCR có các văn phòng tại Hà Nội, TP. HCM, đáp ứng mọi yêu cầu từ xây dựng đến nâng cấp môi trường sản xuất đạt chuẩn

Email: [email protected]

Điện thoại: (+84) 901239008

Địa chỉ:

VP Hà Nội: 9/675 Lạc Long Quân, P. Xuân La, Q. Tây Hồ, TP. Hà Nội

VP Hồ Chí Minh: 15/42 Phan Huy Ích, P.15, Q. Tân Bình, TP.HCM

Hãy liên hệ với VCR để tìm hiểu thêm về lĩnh vực phòng sạch hiệu quả nhất nhé!